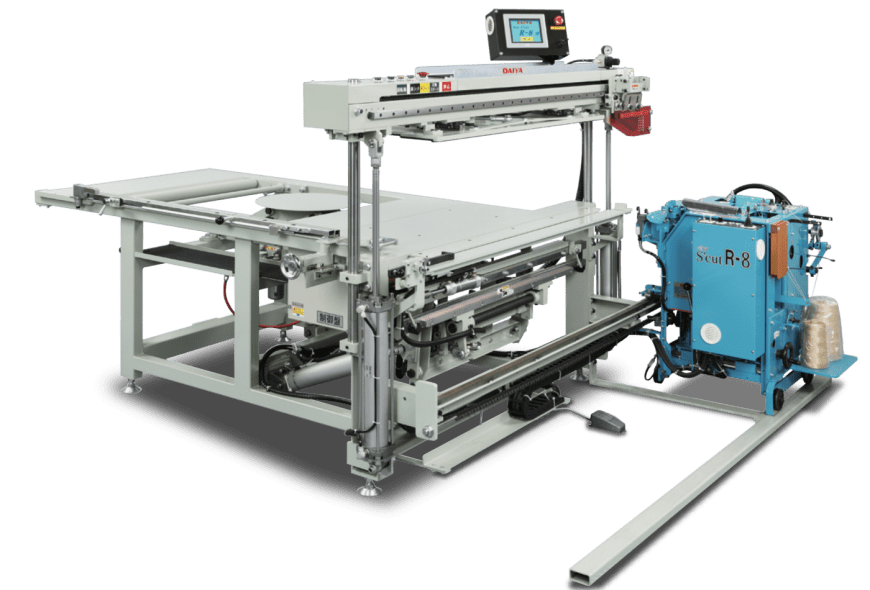

News cut R-8

News cut R-8 doorcase sewing machine << arc needle, ladder sewing >>

... productivity and the safety are ... to further completeness

●Adoption of the expansion of the floor strengthening opening, diagonal movement type turn board, high brightness LED color liquid crystal, cutting department chain cover,

Of the floor thickness adjustment facilitated it, and gave various improvement.

■Characteristic

A height of the floor strengthening board position is 35cm

●The distance from the top surface of the floor stand to a floor strengthening board rose by 15cm than conventional equipment (R-6, R-7).

●It became easy to turn a tatami mat, and there was the tension condition of the table, and work such as the confirmation of the line became comfortable.

●You do not need to bend a waist too much, and the burden to a waist is reduced.

●It became easy to turn a tatami mat, and there was the tension condition of the table, and work such as the confirmation of the line became comfortable.

●You do not need to bend a waist too much, and the burden to a waist is reduced.

The opening which became big

Height of the table tension machine adjustment is easy

●When the thickness of the floor changes at the time of table tension, I turn a steering wheel and only match an arrow with any scale

It became adjustable.

I can easily adjust it quickly.

I cover it to a cutting machine chain and put it on

●A trouble by the involution of the chain, the scattering dirt of the oil with the chain dissolve, too.

●As I cannot see a chain in front, there are no jitters.

●You do not need to bend a waist too much, and the burden to a waist is reduced.

●As I cannot see a chain in front, there are no jitters.

●You do not need to bend a waist too much, and the burden to a waist is reduced.

Safety is improved by a cover

The color liquid crystal display panel deployment

●The control panel adopts a color LCD screen. By the deployment of the high brightness LED, it became easy to see it at the bright place.

●Life of the backlight (LED) improves largely. The start is early, too and starts in approximately three seconds after switching it on.

●The operation touches touch panel lightly. A change, the mode reshuffling of the setting is easy, too.

●As an assembly operation, the trouble are displayed by a message screen, I am reliable at the time of emergency.

●Life of the backlight (LED) improves largely. The start is early, too and starts in approximately three seconds after switching it on.

●The operation touches touch panel lightly. A change, the mode reshuffling of the setting is easy, too.

●As an assembly operation, the trouble are displayed by a message screen, I am reliable at the time of emergency.

Visibility is improved by the high brightness LED deployment

Automatic top thread, lower thread cut-off

●A sewing machine automatically cuts top thread, a lower thread and, after sewing it, goes back. It is saved the lower thread an upper thread.

●I can do thread cutting by manual operation. (manual operation choice possibility automatic with a screen)

●I can do thread cutting by manual operation. (manual operation choice possibility automatic with a screen)

Automatic thread cutting device

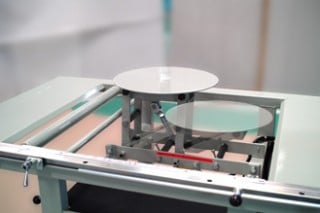

A rotary board moves to the direction where it is easy to turn a tatami mat to

●As I move while a rotary board rises, trouble to push a tatami mat into decreases, and work becomes comfortable.

A rotary board rises diagonally

Adoption of the foot switch

●A rotary board rises when I step on a switch when floor strengthening relaxes. I drop when I step once again.

●Table scissors close when I step on a switch with the state that hyochoki is over.

●Table scissors close when I step on a switch with the state that hyochoki is over.

●As I had both sides of the table by hand and could sandwich the face, I was and became easy to put lines together.

●As I can open the face when I step on a switch once again, I put it together again, and it is easy.

●As I can open the face when I step on a switch once again, I put it together again, and it is easy.

The switch can move to the position that it is easy to set foot on.

Others

●When a thread is cut by a detective device running out of thread or when I disappear, a sewing machine automatically stops it.

(by the setting with the screen, I can coordinate sensitivity)

●As freedom can remove a music collecting ruler of the floor stand, I can perform work of a table substitute, the flip smoothly.

●I can use it for the cutting of the old tatami mat (knife separate sale) and can handle it from the building materials tatami mat to the straw tatami mat.

●The tension of the table is easy to use a fine adjustment by a possibility, and it is convenient.

●I can change the position of the arc needle by steering wheel operation and cope to thin tatami mat 13mm. I can be equipped with the device in a floor occasion, too (option)

(by the setting with the screen, I can coordinate sensitivity)

●As freedom can remove a music collecting ruler of the floor stand, I can perform work of a table substitute, the flip smoothly.

●I can use it for the cutting of the old tatami mat (knife separate sale) and can handle it from the building materials tatami mat to the straw tatami mat.

●The tension of the table is easy to use a fine adjustment by a possibility, and it is convenient.

●I can change the position of the arc needle by steering wheel operation and cope to thin tatami mat 13mm. I can be equipped with the device in a floor occasion, too (option)

■Specifications

Full length

| 2,700mm (9 shakus)

| Height

| 1,470mm (9 sun of 4 shakus)

|

Width

| 1,990mm (6 sun of 6 shakus)

| Tatami mat stand height

| 700mm (3 sun of 2 shakus)

|

Weight

| 610 kg

| ||

Motor

Sewing machine use

Forwarding use

It is for cutting

| Single phase 100V

| Three aspect 200V

| |

200W

| 200W

| ||

400W

| 400W

| ||

200W

| 200W

| ||

Rating power consumption

| 0.5KW (three aspects or single phase)

| ||

Sewing method

| Two thread final sewing (ladder sewing)

| ||

Sewing interval

| 0-45mm (needle turn forwarding) .0-60mm (needle stop forwarding)

| ||

Compressor

| More than 400W (option)

| ||